National Oilheat Research Alliance 47

If it doesn’t, there is a leak in the fuel

line, filter or fittings.

8. Once you’ve double-checked the filter(s)

and valve(s) to establish that they are not

the cause of the leak, change the fuel line.

When installing new copper fuel lines be

sure to use tubing that is polyethylenecoated

and/or sleeved in protective tubing

if the line will contact dirt or concrete.

9. Perform the same test on the new line.

10. If the line checks out, remove the “plug”

then reconnect the line to the fuel tank

and open the fuel valve.

11. Be sure that all air has been bled out

of the line.

12. Let the unit run through several cycles

while you clean the work area and

complete your paperwork.

Alternative To Using The Fuel Unit To

Check Fuel Lines

A vacuum test of the fuel line can also be

performed using a manual vacuum pump,

sometimes referred to as a “push-pull” pump.

Since the check valves on these pumps often

become weak over time, a ball valve should be

threaded into the suction side internal check

valve. If the hand pump does not have a vacuum

gauge on it, install one in the flare fitting

on the line at the tank. Then, instead of running

the burner to generate vacuum, simply pull the

handle of the pump until the desired vacuum is

reached and close the ball valve to tightly close

the line. If the vacuum holds for 30 minutes,

the fuel line is not leaking.

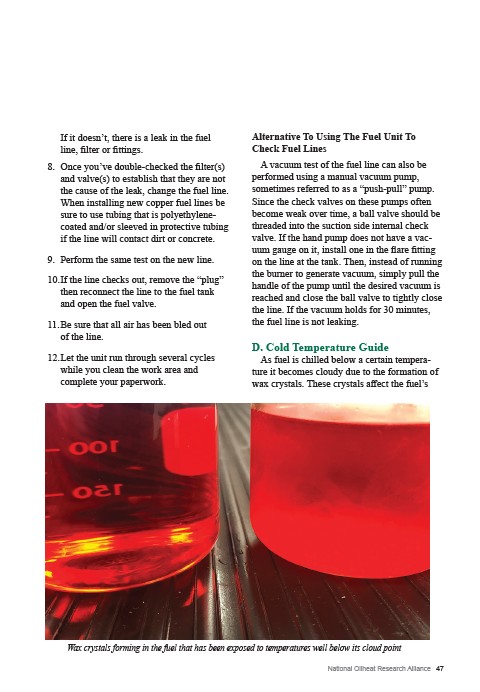

D. Cold Temperature Guide

As fuel is chilled below a certain temperature

it becomes cloudy due to the formation of

wax crystals. These crystals affect the fuel’s

Wax crystals forming in the fuel that has been exposed to temperatures well below its cloud point