valve that will not crack or

break when water within it

freezes. The valve should be

installed so it is situated beneath

the tank with the tank

providing protection from

damage. The valve should be

left closed and plugged with

the handle removed.

An example of a frost free

drain valve can be found at:

morbros.com/sites/default/

files/128-SS-New-01_0.pdf

Maintenance

Properly installed fuel lines require very

little maintenance. Accessible fuel lines should

be inspected periodically, at least during each

tune-up, and replaced as necessary.

Floating Fuel Lines

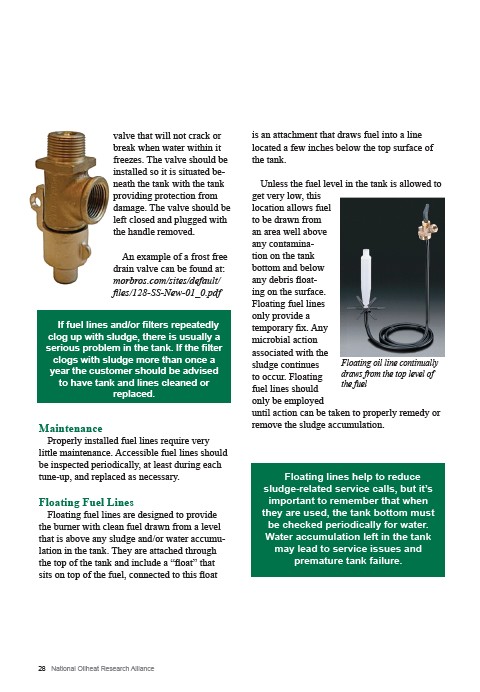

Floating fuel lines are designed to provide

the burner with clean fuel drawn from a level

that is above any sludge and/or water accumulation

in the tank. They are attached through

the top of the tank and include a “float” that

sits on top of the fuel, connected to this float

28 National Oilheat Research Alliance

is an attachment that draws fuel into a line

located a few inches below the top surface of

the tank.

Unless the fuel level in the tank is allowed to

get very low, this

location allows fuel

to be drawn from

an area well above

any contamination

on the tank

bottom and below

any debris floating

on the surface.

Floating fuel lines

only provide a

temporary fix. Any

microbial action

associated with the

sludge continues

Floating oil line continually

to occur. Floating

draws from the top level of

fuel lines should

the fuel

only be employed

until action can be taken to properly remedy or

remove the sludge accumulation.

If fuel lines and/or filters repeatedly

clog up with sludge, there is usually a

serious problem in the tank. If the filter

clogs with sludge more than once a

year the customer should be advised

to have tank and lines cleaned or

replaced.

Floating lines help to reduce

sludge-related service calls, but it’s

important to remember that when

they are used, the tank bottom must

be checked periodically for water.

Water accumulation left in the tank

may lead to service issues and

premature tank failure.