Chapter 8

Tank Inspection &

Maintenance Procedures

Regular inspection of tanks can be a useful

means to identify and correct potential

problems that may affect the tank longevity or

the performance of the heating equipment.

The following pages contain suggested

inspection procedures for initial inspections,

routine inspections and pre-delivery

inspections as well as general maintenance

recommendations. Sample checklists are

provided in Appendix I to assist companies in

inspecting tanks. Local codes and/or company

policies may require changes to these forms.

Initial inspections

NORA recommends that all tanks be

inspected and approved for delivery before

the first delivery is made to a new customer

or to a new tank.

For ASTs, an initial exterior inspection

provides the opportunity to:

• identify staining or wet spots which may

indicate flaws in the shell and/or seams

• observe impacts of corrosion on the tank

and the piping

• identify signs of defects with the related

components

This may help avoid problems in making

deliveries and helps ensure the fill is properly

identified and the vent piping is adequate.

Inspecting tanks before accepting a new

customer also protects your company in

those cases where the prospective customer

is switching suppliers because their current

company has recommended essential

36 National Oilheat Research Alliance

equipment upgrades that the customer does

not want to make. Checking the tank for water

should be included whenever feasible.

Inspection of USTs is generally very limited.

In addition to accessible components of the

fill and vent piping, inspection of the fuel line

piping inside the building is needed.

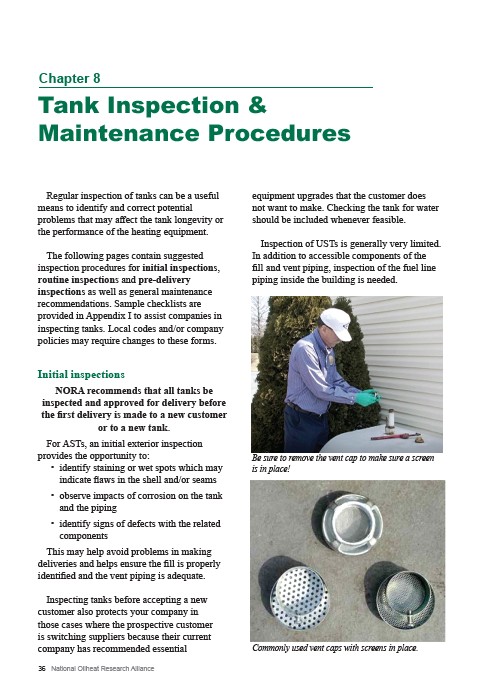

Be sure to remove the vent cap to make sure a screen

is in place!

Commonly used vent caps with screens in place.