Important

National Oilheat Research Alliance 11

Indirect Connection

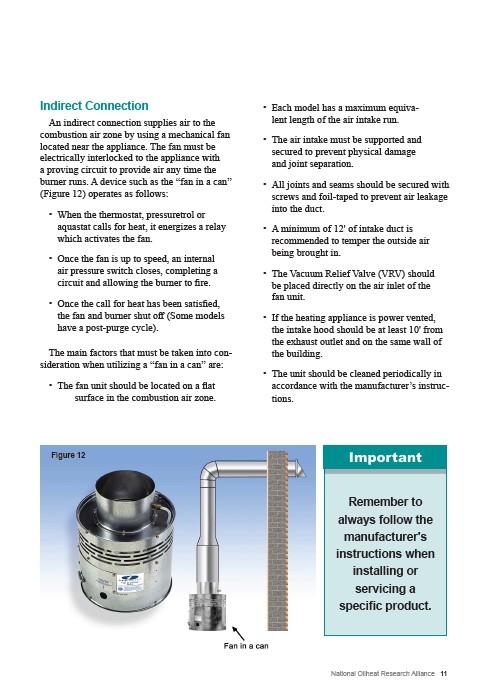

An indirect connection supplies air to the

combustion air zone by using a mechanical fan

located near the appliance. The fan must be

electrically interlocked to the appliance with

a proving circuit to provide air any time the

burner runs. A device such as the “fan in a can”

(Figure 12) operates as follows:

• When the thermostat, pressuretrol or

aquastat calls for heat, it energizes a relay

which activates the fan.

• Once the fan is up to speed, an internal

air pressure switch closes, completing a

circuit and allowing the burner to fire.

• Once the call for heat has been satisfied,

the fan and burner shut off (Some models

have a post-purge cycle).

The main factors that must be taken into con-sideration

when utilizing a “fan in a can” are:

• The fan unit should be located on a flat

surface in the combustion air zone.

• Each model has a maximum equiva-

lent length of the air intake run.

• The air intake must be supported and

secured to prevent physical damage

and joint separation.

• All joints and seams should be secured with

screws and foil-taped to prevent air leakage

into the duct.

• A minimum of 12' of intake duct is

recommended to temper the outside air

being brought in.

• The Vacuum Relief Valve (VRV) should

be placed directly on the air inlet of the

fan unit.

• If the heating appliance is power vented,

the intake hood should be at least 10' from

the exhaust outlet and on the same wall of

the building.

• The unit should be cleaned periodically in

accordance with the manufacturer’s instruc-tions.

Figure 12

Remember to

always follow the

manufacturer's

instructions when

installing or

servicing a

specific product.