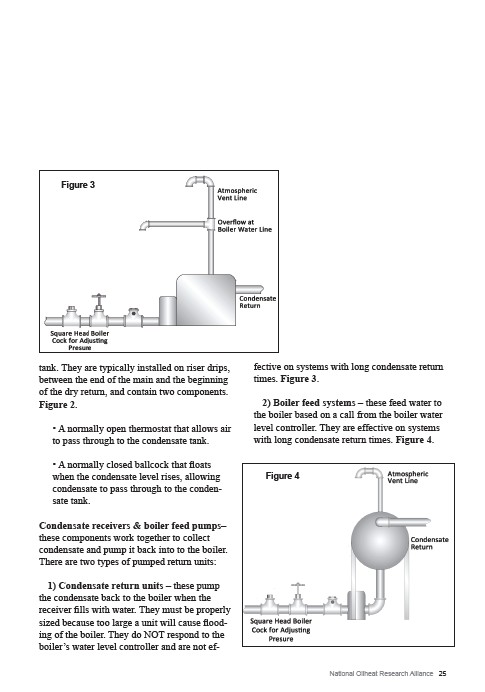

fective on systems with long condensate return

times. Figure 3.

2) Boiler feed systems – these feed water to

the boiler based on a call from the boiler water

level controller. They are effective on systems

with long condensate return times. Figure 4.

National Oilheat Research Alliance 25

Figure 3

tank. They are typically installed on riser drips,

between the end of the main and the beginning

of the dry return, and contain two components.

Figure 2.

• A normally open thermostat that allows air

to pass through to the condensate tank.

• A normally closed ballcock that floats

when the condensate level rises, allowing

condensate to pass through to the condensate

tank.

Condensate receivers & boiler feed pumps–

these components work together to collect

condensate and pump it back into to the boiler.

There are two types of pumped return units:

1) Condensate return units – these pump

the condensate back to the boiler when the

receiver fills with water. They must be properly

sized because too large a unit will cause flooding

of the boiler. They do NOT respond to the

boiler’s water level controller and are not ef-

Figure 4